Introduction of Carbide knife tools!

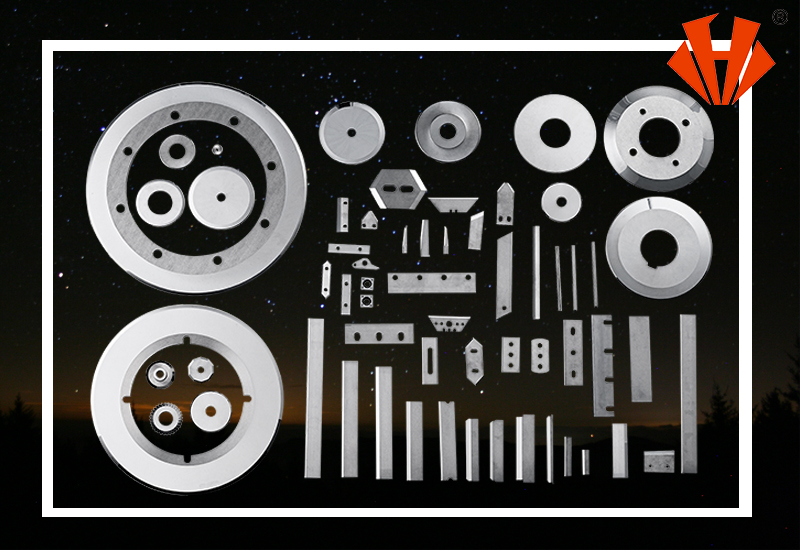

Carbide knife Tools

Carbide knife Tools, especially indexable Carbide knife Tools, are the dominant products in CNC machining tools. Since the 1980s, the variety of solid and indexable Carbide knife Tools or inserts has expanded to various cutting tool fields. Indexable Carbide knife Tools have evolved from simple turning tools and face milling cutters to various precision, complex, and forming tool applications.

A. Types of Carbide knife Tools

Classification by Main Chemical Composition

Carbide knife Tools can be divided into tungsten carbide-based and titanium carbonitride (TiC(N))-based carbides.

Tungsten carbide-based carbides include:

● YG (tungsten-cobalt): High toughness but lower hardness.

● YT (tungsten-cobalt-titanium): Balanced hardness and toughness.

● YW (with rare carbides): Enhanced properties with additives like TaC or NbC.

Main components include tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC), and niobium carbide (NbC), with cobalt (Co) as the common metal binder.

Titanium carbonitride-based carbides use TiC as the primary component, often with other carbides or nitrides, and Mo or Ni as binders.

ISO Classification

The International Organization for Standardization (ISO) classifies cutting carbides into three categories:

● K Class (K10–K40): Equivalent to YG (WC-Co), for cast iron and non-ferrous metals.

● P Class (P01–P50): Equivalent to YT (WC-TiC-Co), for steel.

● M Class (M10–M40): Equivalent to YW (WC-TiC-TaC(NbC)-Co), for versatile applications.

Grades are numbered from 01 to 50, indicating a range from high hardness to maximum toughness.

B. Performance Characteristics of Carbide knife Tools

● High Hardness

Carbide knife Tools are made by powder metallurgy from high-hardness, high-melting-point carbides (hard phase) and metal binders (bonding phase). Their hardness ranges from 89–93 HRA, much higher than high-speed steel (HSS). At 540°C, hardness remains at 82–87 HRA, comparable to HSS at room temperature (83–86 HRA). Hardness varies with carbide type, quantity, grain size, and binder content, generally decreasing as binder content increases. For the same binder content, YT alloys are harder than YG alloys, and alloys with TaC(NbC) have higher high-temperature hardness.

● Flexural Strength and Toughness

The flexural strength of common carbides ranges from 900–1500 MPa. Higher binder content increases flexural strength. For the same binder content, YG (WC-Co) alloys are stronger than YT (WC-TiC-Co) alloys, with strength decreasing as TiC content increases. Carbides are brittle, with impact toughness at room temperature only 1/30 to 1/8 that of HSS.

C. Applications of Common Carbide knife Tools

● YG Class Carbides

YG alloys are mainly used for machining cast iron, non-ferrous metals, and non-metallic materials. Fine-grain YG alloys (e.g., YG3X, YG6X) have higher hardness and wear resistance than medium-grain alloys at the same cobalt content, suitable for machining special hard cast iron, austenitic stainless steel, heat-resistant alloys, titanium alloys, hard bronze, and wear-resistant insulating materials.

● YT Class Carbides

YT alloys have high hardness, good heat resistance, and better high-temperature hardness and compressive strength than YG alloys, with superior oxidation resistance. They are ideal for high heat and wear resistance applications and suitable for machining plastic materials like steel but not titanium or silicon-aluminum alloys. Higher TiC content grades are preferred for enhanced heat and wear resistance.

● YW Class Carbides

YW alloys combine the properties of YG and YT alloys, offering good overall performance. They are suitable for machining steel, cast iron, and non-ferrous metals. With increased cobalt content, YW alloys achieve high strength, making them ideal for rough machining and interrupted cutting of difficult-to-machine materials.

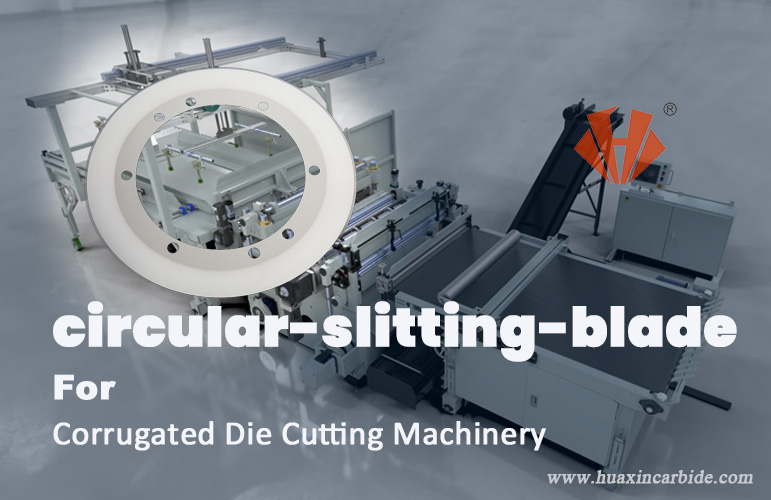

Chengdu Huaxin Cemented Carbide Company: A Leading Manufacturer

Chengdu Huaxin Cemented Carbide Company is one of the leading players in China’s tungsten carbide blade industry. Known for its high-quality manufacturing standards and commitment to technological innovation, Huaxin has established a strong reputation in both domestic and international markets.

Why Choose Chengdu Huaxin Cemented Carbide?

- Quality Standards: Huaxin’s products adhere to strict quality standards, ensuring reliability and performance.

- Advanced Manufacturing Facilities: The company employs state-of-the-art manufacturing equipment and technology to produce blades that meet precise specifications.

- Wide Range of Products: Huaxin offers various types of tungsten carbide blades for different industries, including custom options tailored to specific needs.

- Competitive Pricing: The company’s large-scale production and efficient processes enable it to offer competitive prices without compromising on quality.

- After-Sales Service: Huaxin is known for its excellent customer service, providing technical support and guidance to ensure optimal product performance.

Know more About Huaxin Cemented Carbide

To know more about prices and services, please click here>>> Contact us

--------

To know more about our Company, please click here>>> About us

--------

To know more about our portfolio, please click here>>>Our Products

--------

To know more about our AfterSales and other People also ask questions, please click here >>> FAQ

Post time: Jun-17-2025