Cemented carbide tools dominate in CNC machining tools. In some countries, over 90% of turning tools and more than 55% of milling tools are made of cemented carbide. Additionally, cemented carbide is commonly used to manufacture general tools such as drills and face milling cutters. The use of cemented carbide is also increasing in complex tools like reamers, end mills, medium and large modulus gear cutters for machining hardened tooth surfaces, and broaches. The cutting efficiency of cemented carbide tools is 5 to 8 times that of high-speed steel (HSS) tools. The amount of metal removed per unit of tungsten content is about 5 times greater than that of HSS. Therefore, widely using cemented carbide as a tool material is one of the most effective ways to utilize resources efficiently, improve cutting productivity, and enhance economic benefits.

Classification of Cemented Carbide Tool Materials

Based on the main chemical composition, cemented carbide can be divided into tungsten carbide-based cemented carbide and titanium carbonitride (Ti(C,N))-based cemented carbide, as shown in Table 3-1.

Tungsten carbide-based cemented carbide includes:

Tungsten-cobalt (YG)

Tungsten-cobalt-titanium (YT)

With added rare carbides (YW)

Each type has its own advantages and disadvantages. The added carbides include tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC), niobium carbide (NbC), etc., with cobalt (Co) being the commonly used metal binder phase.

Titanium carbonitride-based cemented carbide primarily consists of TiC (some with other carbides or nitrides added), with molybdenum (Mo) and nickel (Ni) as the commonly used metal binder phases.

Based on grain size, cemented carbide can be classified into:

Ordinary cemented carbide

Fine-grained cemented carbide

Ultrafine-grained cemented carbide

According to GB/T 2075—2007, the letter symbols are as follows:

HW: Uncoated cemented carbide mainly containing tungsten carbide (WC) with a grain size of ≥1μm

HF: Uncoated cemented carbide mainly containing tungsten carbide (WC) with a grain size of <1μm

HT: Uncoated cemented carbide mainly containing titanium carbide (TiC) or titanium nitride (TiN) or both (also known as cermet)

HC: The aforementioned cemented carbides with a coating

The International Organization for Standardization (ISO) classifies cutting cemented carbides into three categories:

K class (K10 to K40):

Equivalent to China’s YG class (mainly composed of WC-Co)

P class (P01 to P50):

Equivalent to China’s YT class (mainly composed of WC-TiC-Co)

M class (M10 to M40):

Equivalent to China’s YW class (mainly composed of WC-TiC-TaC(NbC)-Co)

Each category’s grades are represented by a number between 01 and 50, indicating a series of alloys from the highest hardness to the greatest toughness, for selection in various cutting processes and machining conditions for different workpiece materials. If necessary, an intermediate code can be inserted between two adjacent classification codes, such as P15 between P10 and P20, or K25 between K20 and K30, but no more than one. In special cases, the P01 classification code can be further subdivided by adding another digit separated by a decimal point, such as P01.1, P01.2, etc., to further distinguish the wear resistance and toughness of materials for finishing operations.

Performance of Cemented Carbide Tool Materials

1. HardnessCemented carbide contains a large amount of hard carbides (such as WC, TiC), making its hardness much higher than that of high-speed steel materials. The higher the hardness of cemented carbide, the better its wear resistance, which is generally much higher than that of high-speed steel.

The higher the cobalt binder phase content, the lower the hardness of the alloy.

Since TiC is harder than WC, WC-TiC-Co alloys have higher hardness than WC-Co alloys. The more TiC content, the higher the hardness.

Adding TaC to WC-Co alloys increases hardness by approximately 40 to 100 HV; adding NbC increases it by 70 to 150 HV.

2. StrengthThe flexural strength of cemented carbide is only about 1/3 to 1/2 that of high-speed steel materials.

The higher the cobalt content, the higher the strength of the alloy.

Alloys containing TiC have lower strength than those without TiC; the more TiC content, the lower the strength.

Adding TaC to WC-TiC-Co cemented carbide increases its flexural strength and significantly enhances the cutting edge’s resistance to chipping and breakage. As TaC content increases, fatigue strength also improves.

The compressive strength of cemented carbide is 30% to 50% higher than that of high-speed steel.

3. ToughnessThe toughness of cemented carbide is much lower than that of high-speed steel.

Alloys containing TiC have lower toughness than those without TiC; as TiC content increases, toughness decreases.

In WC-TiC-Co alloys, adding an appropriate amount of TaC can increase toughness by about 10% while maintaining heat resistance and wear resistance.

Due to its lower toughness, cemented carbide is not suitable for conditions with strong impacts or vibrations, especially at low cutting speeds where adhesion and chipping are more severe.

4. Thermal Physical PropertiesThe thermal conductivity of cemented carbide is approximately 2 to 3 times higher than that of high-speed steel.

Since the thermal conductivity of TiC is lower than that of WC, WC-TiC-Co alloys have lower thermal conductivity than WC-Co alloys. The more TiC content, the poorer the thermal conductivity.

5. Heat ResistanceCemented carbide has much higher heat resistance than high-speed steel and can perform cutting at 800 to 1000°C with good resistance to plastic deformation at high temperatures.

Adding TiC increases high-temperature hardness. Since TiC’s softening temperature is higher than WC’s, the hardness of WC-TiC-Co alloys decreases more slowly with temperature than WC-Co alloys. The more TiC and the less cobalt, the smaller the decrease.

Adding TaC or NbC (with higher softening temperatures than TiC) further increases high-temperature hardness and strength.

6. Anti-Adhesion PropertiesThe adhesion temperature of cemented carbide is higher than that of high-speed steel, giving it better resistance to adhesion wear.

Cobalt’s adhesion temperature with steel is much lower than WC’s; as cobalt content increases, adhesion temperature decreases.

TiC’s adhesion temperature is higher than WC’s, so WC-TiC-Co alloys have a higher adhesion temperature (about 100°C higher) than WC-Co alloys. TiO2 formed at high temperatures during cutting reduces adhesion.

TaC and NbC have higher adhesion temperatures than TiC, improving anti-adhesion properties. TaC’s affinity with workpiece materials is only a fraction to a few tenths of WC’s.

7. Chemical StabilityThe wear resistance of cemented carbide tools is closely tied to their physical and chemical stability at working temperatures.

The oxidation temperature of cemented carbide is higher than that of high-speed steel.

TiC’s oxidation temperature is much higher than WC’s, so WC-TiC-Co alloys gain less oxidation weight at high temperatures than WC-Co alloys; the more TiC, the stronger the oxidation resistance.

TaC’s oxidation temperature is also higher than WC’s, and alloys with TaC and NbC have improved resistance to high-temperature oxidation. However, higher cobalt content makes oxidation easier.

Why Choose Chengduhuaxin Carbide?

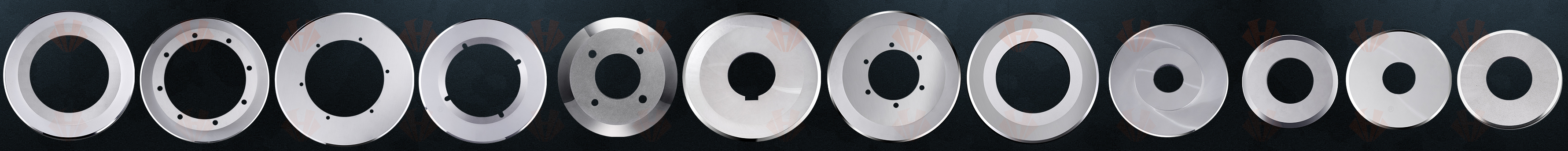

Chengduhuaxin Carbide stands out in the market due to its commitment to quality and innovation. Their tungsten carbide carpet blades and tungsten carbide slotted blades are engineered for superior performance, providing users with tools that deliver clean, precise cuts while withstanding the rigors of heavy industrial use. With a focus on durability and efficiency, Chengduhuaxin Carbide’s slotted blades offer an ideal solution for industries requiring reliable cutting tools.

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Jul-23-2025