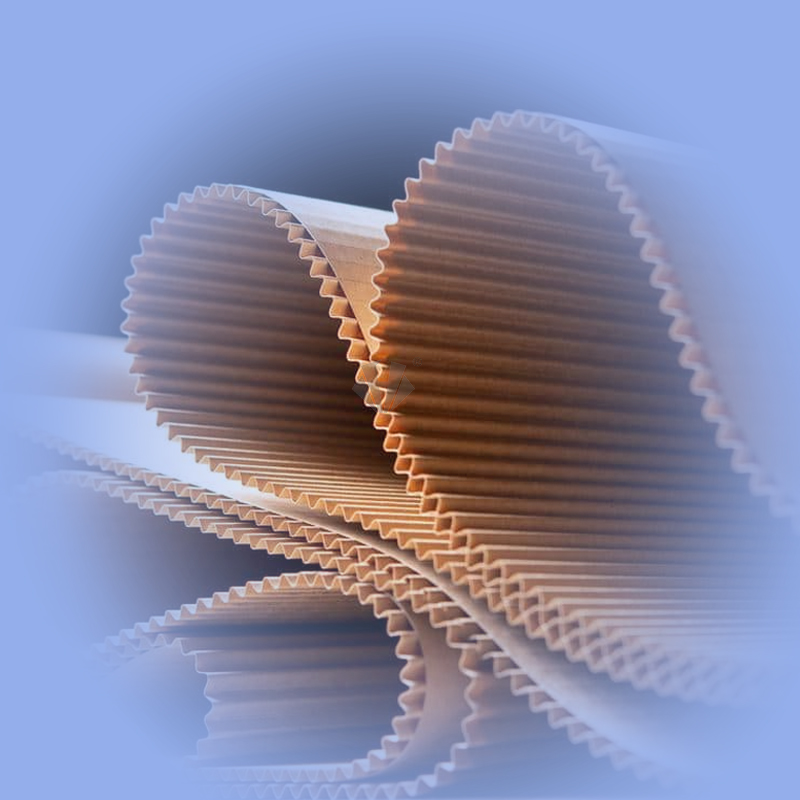

Challenges arise during the slitting process When dealing with low grammage corrugated cardboard, they are characterized by corrugated cardboard’s thinness and lightweight nature...Additionally, the tungsten carbide slitting blades used must meet specific requirements to ensure effective cutting and to mitigate these issues.

Common Issues with Slitting Low Grammage Corrugated Cardboard

● Tearing or Ripping

Low grammage corrugated cardboard lacks the structural strength of thicker varieties, making it prone to tearing rather than achieving a clean cut. This can occur if the blades are not sufficiently sharp or if excessive cutting force is applied, resulting in jagged edges or damaged material.

● Blade Dulling

Despite its thinness, corrugated cardboard can be abrasive, especially if it contains recycled fibers or mineral content. This abrasiveness causes slitting blades to dull quickly, leading to inconsistent cuts and increased maintenance needs.

● Snagging on Flutes

The fluted layer in corrugated cardboard can cause the blades to catch or snag during slitting. This may result in uneven cuts, damage to the material, or even blade wear if the edge design is not suited to the cardboard’s structure.

● Deformation or Warping

Thin cardboard is susceptible to deformation or warping under the pressure and heat generated during slitting. This can compromise the accuracy of the cuts and the quality of the final product.

● Dust and Debris Generation

Slitting low grammage cardboard often produces fine dust or debris, which can accumulate on the blades or within the slitting machine. This buildup may interfere with cutting precision and require regular cleaning.

Requirements for Tungsten Carbide Slitting Blades

When tackle these challenges above and ensure efficient slitting of low grammage corrugated cardboard, tungsten carbide slitting blades must possess the following properties and features:

Exceptional Sharpness

The blades must be extremely sharp to produce clean, precise cuts without tearing the thin material. A sharp edge reduces the cutting force needed, minimizing the risk of ripping or deforming the cardboard.

High Hardness and Wear Resistance

Tungsten carbide’s inherent hardness makes it ideal for cutting abrasive materials like corrugated cardboard. For low grammage applications, the blades must maintain their sharpness over time, requiring a high-quality carbide grade with excellent wear resistance to reduce the frequency of sharpening or replacement.

Optimized Edge Geometry

The blade’s cutting edge should be tailored to thin materials. For example, a fine edge with a small radius (e.g., 5–10 µm) ensures precision, while a slightly rounded edge (e.g., 15–20 µm) may help distribute forces and prevent tearing. The geometry depends on the cardboard’s thickness and the slitting setup.

Low Friction and Heat Generation

Excessive heat can warp or damage thin cardboard. Blades should feature polished surfaces or coatings, such as Titanium Nitride (TiN), to minimize friction and heat buildup during cutting, preserving the material’s integrity.

Brittleness Management

While tungsten carbide is hard, it is also brittle. Blades must be carefully installed and aligned in the slitting machine to avoid chipping or cracking, particularly during high-speed operations.

Machine Compatibility

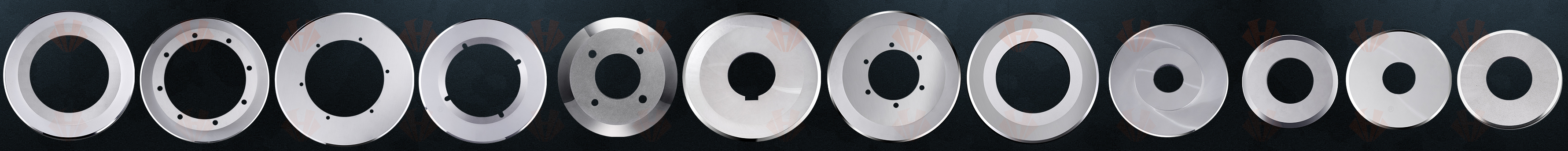

The blades must match the specifications of the slitting machine (e.g., size, shape, and mounting method). Different machines, such as those from BHS or Fosber, may require specific blade designs to ensure optimal performance.

Durability for Continuous Operation

In high-volume production, blades need to withstand prolonged use without losing effectiveness. Tungsten carbide’s toughness supports this, but the blade design must account for the unique challenges of low grammage cardboard to maintain efficiency.

Slitting low grammage corrugated cardboard presents challenges such as tearing, blade dulling, and material deformation due to its thin and lightweight nature.

Tungsten carbide slitting blades must be exceptionally sharp, wear-resistant, and designed with optimized edge geometry to address these issues effectively. Additionally, minimizing friction and ensuring compatibility with the slitting machine are critical for achieving high-quality cuts and maintaining production efficiency. By meeting these requirements, manufacturers can overcome the common problems and ensure reliable performance in processing low grammage corrugated cardboard.

Why Choose Chengduhuaxin Carbide?

Chengduhuaxin Carbide stands out in the market due to its commitment to quality and innovation. Their tungsten carbide carpet blades and tungsten carbide slotted blades are engineered for superior performance, providing users with tools that deliver clean, precise cuts while withstanding the rigors of heavy industrial use. With a focus on durability and efficiency, Chengduhuaxin Carbide’s slotted blades offer an ideal solution for industries requiring reliable cutting tools.

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Jun-20-2025