Tungsten carbide slitting blades are widely used in the corrugated cardboard industry due to their hardness and wear resistance. However, during the slitting process, these blades can still suffer damage, leading to reduced performance, increased downtime, and higher operational costs. Understanding the common causes of blade damage and implementing targeted improvements is essential for optimizing the slitting process. Below, I outline the primary reasons for blade damage and the corresponding strategies for blade improvement.

Reasons for Tungsten Carbide Slitting Blade Damage

● Abrasive Wear

Corrugated cardboard, particularly when made from recycled fibers or containing mineral content (e.g., fillers or coatings), can be highly abrasive. This abrasiveness causes the blade's cutting edge to wear down over time, leading to dullness and reduced cutting efficiency.

● Adhesive Buildup

The adhesives used in the lamination of corrugated cardboard layers can stick to the blade during cutting. This buildup affects the blade's sharpness, increases friction, and can cause the blade to overheat or even break under stress.

● Improper Blade Installation

If the blade is not correctly aligned or securely mounted in the slitting machine, it can experience uneven wear or sudden breakage. Misalignment can also lead to excessive vibration, further accelerating damage.

● Excessive Cutting Force

Applying too much force during the slitting process, especially when cutting dense or tough cardboard, can cause the blade to chip or crack. This is particularly problematic if the blade encounters unexpected material variations, such as knots or dense areas in the cardboard.

● Heat Generation

Friction between the blade and the cardboard generates heat, which can soften the tungsten carbide material, leading to premature wear, deformation, or even thermal cracking. Excessive heat also exacerbates adhesive buildup.

● Material Inconsistencies

Variations in the cardboard's thickness, density, or composition (e.g., moisture content or fiber orientation) can create unexpected stress on the blade. These inconsistencies may cause the blade to experience sudden impacts or uneven loading, leading to chipping or breakage.

Strategies for Blade Improvement

To address the aforementioned issues and enhance the durability and performance of tungsten carbide slitting blades, the following strategies can be employed:

●●● Material Enhancement

Use a higher grade of tungsten carbide with finer grain structures or incorporate additives (e.g., cobalt binders or other carbides) to increase the blade's hardness, toughness, and wear resistance. This helps the blade withstand abrasive wear and reduces the frequency of sharpening or replacement.

●●●Coating Technologies

Apply advanced coatings such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), or Diamond-Like Carbon (DLC) to the blade surface. These coatings reduce friction, improve wear resistance, and prevent adhesive buildup by creating a smoother, harder surface that resists sticking and abrasion.

●●● Edge Geometry Optimization

Tailor the blade's cutting edge geometry to the specific characteristics of corrugated cardboard. For example:

A sharper edge (e.g., with a smaller edge radius) can provide cleaner cuts and reduce tearing.

A slightly rounded or honed edge can distribute cutting forces more evenly, reducing the risk of chipping when encountering material inconsistencies.

Additionally, optimizing the blade's angle and profile can improve its ability to handle the fluted structure of corrugated cardboard without snagging.

●●●Heat Dissipation

Improve the blade design to enhance heat dissipation during cutting. This can be achieved by:

Incorporating cooling channels or using blade materials with better thermal conductivity.

Designing the blade with a larger surface area or heat sinks to dissipate heat more effectively.

Reducing heat buildup helps maintain the blade's hardness and prevents thermal damage.

●●● Quality Control

Implement stricter quality control measures during the manufacturing process to ensure consistency in blade properties, such as hardness, edge sharpness, and dimensional accuracy. This reduces the likelihood of defects that could lead to premature failure.

●●●User Education and Maintenance

Provide comprehensive guidelines and training for proper blade installation, alignment, and maintenance. Educating operators on the correct cutting parameters (e.g., speed, force, and lubrication) can minimize human error and prevent damage due to improper handling.

Tungsten carbide slitting blades used in corrugated cardboard cutting can suffer damage due to abrasive wear, adhesive buildup, improper installation, excessive cutting force, heat generation, and material inconsistencies. To mitigate these issues, blade improvements should focus on enhancing the material's wear resistance, applying friction-reducing coatings, optimizing edge geometry, improving heat dissipation, and ensuring strict quality control. Additionally, educating users on proper blade handling and maintenance is crucial for extending blade life and maintaining cutting efficiency. By implementing these strategies, manufacturers can significantly reduce blade damage, improve operational reliability, and lower overall production costs.

Why Choose Chengduhuaxin Carbide?

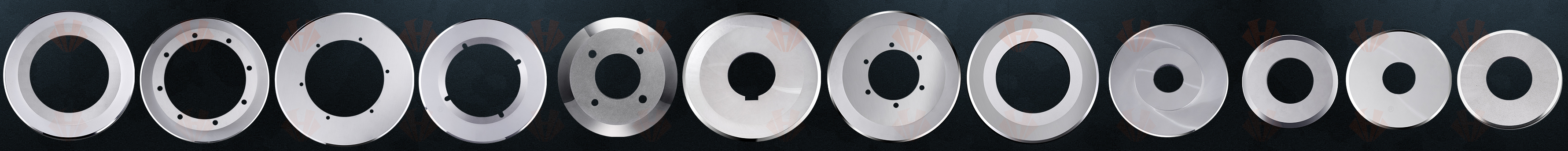

Chengduhuaxin Carbide stands out in the market due to its commitment to quality and innovation. Their tungsten carbide carpet blades and tungsten carbide slotted blades are engineered for superior performance, providing users with tools that deliver clean, precise cuts while withstanding the rigors of heavy industrial use. With a focus on durability and efficiency, Chengduhuaxin Carbide’s slotted blades offer an ideal solution for industries requiring reliable cutting tools.

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Jun-18-2025