Manufacturing Process of Cemented CarbideIt is often said that to improve machining efficiency, the three key cutting parameters—cutting speed, depth of cut, and feed rate—must be optimized, as this is typically the simplest and most direct approach. However, increasing these parameters is often limited by the conditions of existing machine tools. Therefore, the most economical and convenient method is to select the right tool.Cemented carbide tools are currently the mainstream in the tool market. The quality of cemented carbide is determined by three factors: the cemented carbide matrix (skeleton), the structure and shape of the blade (flesh), and the coating (skin). Today, we’ll take a deep dive into machining tools, from the "skeleton to the flesh."Composition of Cemented Carbide MatrixThe cemented carbide matrix consists of two main components:

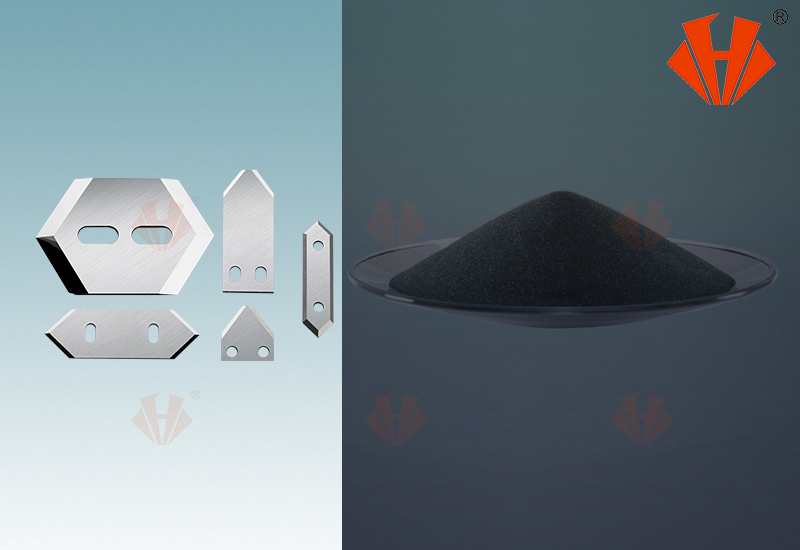

Hardening Phase: This includes materials like tungsten carbide (WC) and titanium carbide (TiC), which start as powders.

Don’t underestimate these powders—they are the primary raw materials for all cemented carbides.

Tungsten Carbide Production: Tungsten carbide is made from tungsten and carbon. Tungsten powder with an average particle size of 3–5 μm is mixed with carbon black in a ball mill for dry blending. After thorough mixing, the mixture is placed in a graphite tray and heated in a graphite resistance furnace to 1400–1700°C. At this high temperature, a reaction produces tungsten carbide.

Properties: Tungsten carbide is an extremely hard yet brittle material with a melting point above 2000°C, sometimes exceeding 4000°C. It determines the alloy’s high hardness and wear resistance.

Binder Metal: Typically, iron-group metals like cobalt (Co) and nickel (Ni) are used, with cobalt being the most common in machining.

For example, when tungsten carbide is mixed with cobalt, the cobalt content is critical to the properties of cemented carbide. Higher cobalt content improves toughness, while lower cobalt content enhances hardness and wear resistance.

Manufacturing Process

1. Powder Preparation (Wet Milling)In the milling chamber, raw materials are ground to the desired particle size in an environment with ethanol, water, and organic binders. This process, known as wet milling, involves adding organic or inorganic solvents as grinding aids.

▶ Why Wet Milling?

▶Dry milling can only grind materials to the micron level (e.g., above 20 μm) because, below this size, electrostatic attraction causes severe particle agglomeration, making further grinding difficult.

▶Wet milling, with the impact of grinding aids, can reduce particle size to a few microns or even nanometers.

▶Duration: Depending on the raw materials, wet milling takes approximately 8–55 hours, resulting in a uniform suspension of the raw materials.

2. Spray DryingThe liquid mixture is pumped into a spray dryer, where hot nitrogen gas evaporates the ethanol and water, leaving behind uniformly sized granular powder.

▶The dried powder consists of spherical particles with diameters ranging from 20–200 μm. To put this in perspective, the finest powder is less than half the thickness of a human hair.

▶The dried slurry is sent for quality inspection to ensure consistency.

3. PressingThe inspected powder is fed into a pressing machine to manufacture tool inserts.

▶The pressing mold is placed in the machine, and the punch and die are controlled to press the powder into the basic shape and size of the tool.

▶Depending on the insert type, the required pressure can reach up to 12 tons.

▶After pressing, each insert is weighed to ensure quality and precision.

4. SinteringThe freshly pressed inserts are very fragile and require hardening in a sintering furnace.

▶The inserts undergo 13 hours of heat treatment at 1500°C, where the molten cobalt binds with the tungsten carbide particles. At 1500°C, steel would melt as quickly as chocolate.

▶During sintering, polyethylene glycol (PEG) in the mixture evaporates, and the insert’s volume shrinks by approximately 50%, achieving a certain level of hardness.

5. Surface Treatment (Honing and Coating)To achieve precise dimensions, the inserts undergo honing to grind the top and bottom surfaces.

▶Since sintered cemented carbide inserts are extremely hard, industrial diamond grinding wheels are used for precision grinding.

▶This step demands high precision in grinding technology. For example, Sweden employs advanced 6-axis grinding technology to meet extremely strict tolerance requirements.

After grinding, the inserts are cleaned, coated, and subjected to final quality inspection.

Why Choose Chengduhuaxin Carbide?

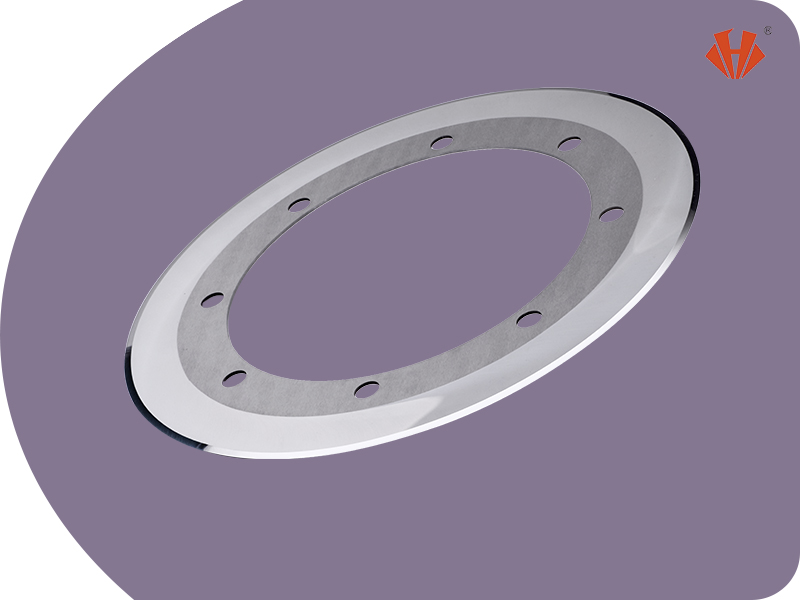

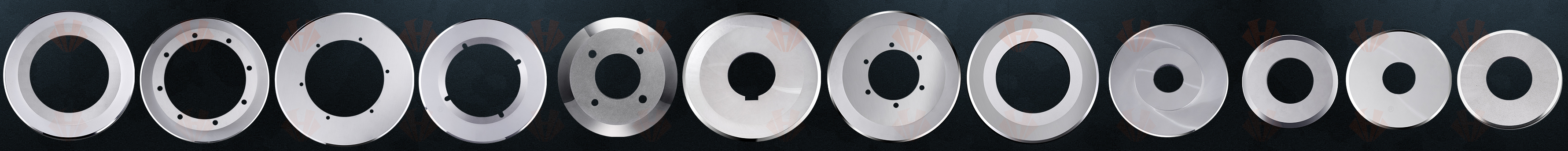

Chengduhuaxin Carbide stands out in the market due to its commitment to quality and innovation. Their tungsten carbide carpet blades and tungsten carbide slotted blades are engineered for superior performance, providing users with tools that deliver clean, precise cuts while withstanding the rigors of heavy industrial use. With a focus on durability and efficiency, Chengduhuaxin Carbide’s slotted blades offer an ideal solution for industries requiring reliable cutting tools.

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Jul-18-2025