Typical cemented carbide tool materials mainly include tungsten carbide-based cemented carbide, TiC(N)-based cemented carbide, cemented carbide with added TaC (NbC), and ultrafine-grained cemented carbide. The performance of cemented carbide materials is primarily determined by the added strengthening phases.

Cemented Carbide with Added TaC (NbC)

Adding TaC (NbC) to cemented carbide is an effective method to enhance its performance. In TiC/Ni/Mo alloys, replacing part of the TiC with carbides like WC and TaC, which offer better toughness, improves the cemented carbide's performance and expands its application range. The addition of WC and TaC enhances:

● Toughness

● Elastic modulus

● Resistance to plastic deformation

● High-temperature strength

It also improves thermal conductivity and thermal shock resistance, making the tool more suitable for interrupted cutting.In WC-Co alloys, performance can be improved by adding 0.5% to 3% (mass fraction) of carbides such as TaC, NbC, Cr3C2, VC, TiC, or HfC. The main objectives include:

● Grain refinement

● Maintaining a uniform crystal structure without significant recrystallization

● Increasing hardness and wear resistance without compromising toughness

Additionally, these additives enhance:

● High-temperature hardness

● High-temperature strength

● Oxidation resistance

During cutting, a tough, self-compensating oxide film forms, which resists adhesive and diffusive wear when machining certain metals or alloys. This improves the tool's wear resistance and increases its ability to resist crater wear and flank wear. These benefits become more pronounced as the cobalt content in the cemented carbide increases.

● Cemented carbide with 1% to 3% (mass fraction) TaC (NbC) can machine various cast irons, including extra-hard cast iron and alloy cast iron.

● Low-cobalt alloys with 3% to 10% (mass fraction) TaC (NbC), such as YG6A, YG8N, and YG813, are versatile. They can process:

Chilled cast iron

Ductile cast iron

Non-ferrous metals

Difficult-to-machine materials like stainless steel, hardened steel, and high-temperature alloys

These are commonly known as general-purpose alloys (YW).Increasing the cobalt content appropriately boosts the strength and toughness of this type of cemented carbide, making it suitable for rough machining and interrupted cutting of difficult-to-machine materials. Applications include:

● Skinning large steel castings and forgings

● Turning, planing, and milling of austenitic steel and heat-resistant alloys

● Machining with large rake angles, large cutting sections, and medium to low speeds

● Rough turning on automatic, semi-automatic, and multi-tool lathes

● Manufacturing drills, gear hobs, and other tools with high cutting edge strength**

In WC-TiC-Co alloys, excessive TiC content increases sensitivity to thermal cracking, leading to greater brittleness. Adding TaC to low-TiC, high-cobalt WC-Ti-Co alloys improves:

● Toughness

● Heat resistance

● Oxidation resistance

While TiC reduces thermal shock resistance, TaC compensates for this, making the alloy suitable for milling operations.Less expensive alternatives like NbC or Hf-Nb carbides (mass fraction: Hf-60%, Nb-40%) can substitute for TaC. In TiC-Ni-Mo alloys, adding TiN, WC, and TaC simultaneously significantly enhances:

● Hardness

● Flexural strength

● Oxidation resistance

● Thermal conductivity

at high temperatures (900–1000°C).

Ultrafine-Grained Cemented Carbide

Refining the grains of cemented carbide reduces the hard phase size, increasing the surface area of hard phase grains and the bonding strength between grains. The binder phase distributes more evenly around them, improving:

Hardness

Wear resistance

Increasing the cobalt content appropriately also boosts flexural strength. Ultrafine-grained cemented carbide, composed of extremely small WC and Co particles, combines:

The high hardness of cemented carbide

The strength of high-speed steel

Grain size comparisons:

Ordinary cemented carbide: 3–5 μm

General fine-grained cemented carbide: ~1.5 μm

Submicron-grained alloys: 0.5–1 μm

Ultrafine-grained cemented carbide: WC grain size below 0.5 μm

Grain refinement improves:

Hardness

Wear resistance

Flexural strength

Chipping resistance

High-temperature hardness

Compared to ordinary cemented carbide of the same composition, ultrafine-grained cemented carbide offers:

Hardness increase of more than 2 HRA

Flexural strength increase of 600–800 MPa

Typical properties:

Cobalt content: 9%–15%

Hardness: 90–93 HRA

Flexural strength: 2000–3500 MPa

Grades produced in China include YS2 (YG10H, YG10HT), YM051 (YH1), YM052 (YH2), YM053 (YH3), YD05 (YC09), YD10 (YG1101), B60, YG610, YG643, and YD05.Due to its extremely fine grains, ultrafine-grained cemented carbide can be ground to very sharp cutting edges with low surface roughness, making it ideal for precision tools like:

Broaches

Reamers

Precision hobs

It excels in machining with small depths of cut and feed rates. It is also suitable for small-sized tools such as:

Small drills

Small milling cutters

Small broaches

Small hobs

Replacing high-speed steel tools, its lifespan is 10–40 times longer, potentially exceeding 100 times.Ultrafine-grained cemented carbide tools are especially suited for machining:

Iron-based and nickel-based high-temperature alloys

Titanium alloys

Heat-resistant stainless steels

Sprayed, welded, and clad materials (e.g., iron-based, nickel-based, cobalt-based, superhard self-fluxing alloy powders, cobalt-chromium-tungsten series)

Ultra-high-strength steels

Hardened steels

High-hardness materials like high-chromium and nickel-chilled cast irons

When machining difficult-to-machine materials, its lifespan is 3–10 times longer than that of ordinary cemented carbide.

Why Choose Chengduhuaxin Carbide?

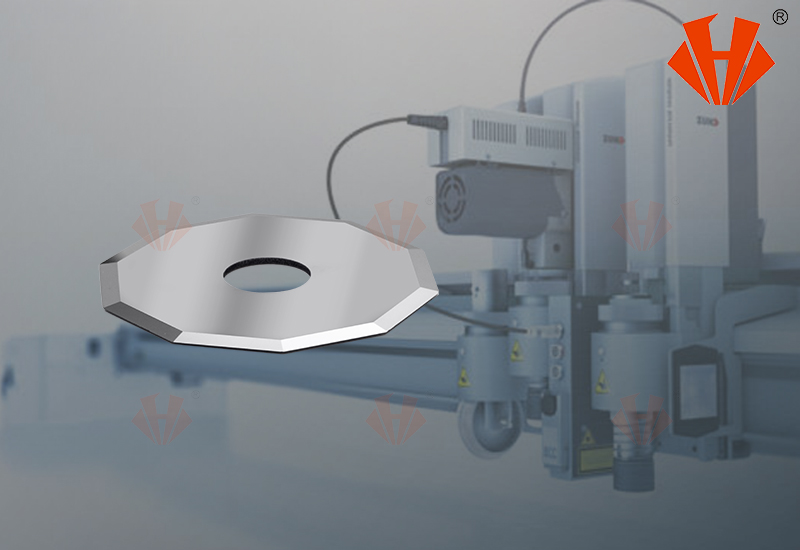

Chengduhuaxin Carbide stands out in the market due to its commitment to quality and innovation. Their tungsten carbide carpet blades and tungsten carbide slotted blades are engineered for superior performance, providing users with tools that deliver clean, precise cuts while withstanding the rigors of heavy industrial use. With a focus on durability and efficiency, Chengduhuaxin Carbide’s slotted blades offer an ideal solution for industries requiring reliable cutting tools.

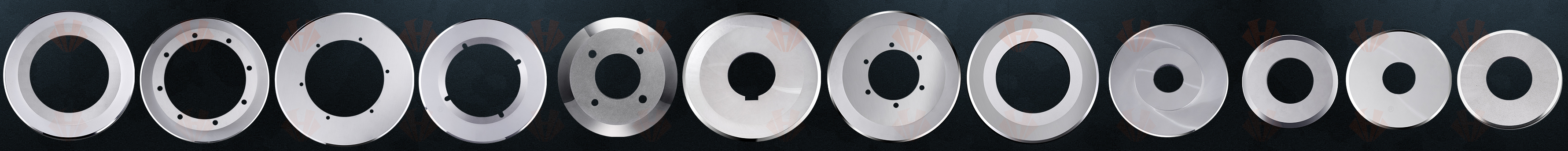

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Jul-14-2025