Industry News

-

Top 5 Maintenance Tips to Extend the Life of Tobacco Circular Knives

Tobacco cutting is not gentle. It looks soft. It is not. Tobacco leaves carry moisture. They carry sugar. They carry fine dust. All of this attacks the cutting edge. Fast. Tobacco lines also run non-stop. High speed. Tight tolerance. No excuses. If you are using tungsten...Read more -

Corrugated Board Slitting: The Real Challenges — And Which Knife Actually Works

Corrugated Board Slitting: The Real Challenges — And Which Knife Actually Works Corrugated board looks easy to cut. It is not. It is rough. It is abrasive. And it never stops moving. In modern corrugato...Read more -

Which Material is Best for Corrugated Slitter Knives? Tungsten Carbide vs. HSS?

Which Material is Best for Corrugated Slitter Knives? Tungsten Carbide vs. HSS? First Off: What Are These Materials Anyway? Let's start with the basics. HSS...Read more -

2026 Guide: How to Choose the Right Short Fiber Cutting Blades for the Textile Industry

Hey there, if you're in the textile game, you know cutting short fibers like polyester, nylon, or cotton blends is no joke. It's all about getting clean, precise cuts without fraying or wasting material, especially when you're churning out stuff at high speeds. As a fact...Read more -

Challenges in Cutting Rayon and Textile Processing

Exploring How Tungsten Carbide Knives Address Cutting Pain Points in the Textile Industry. Dealing with "Soft Yet Abrasive" Materials: Rayon fibers themselves are soft, but the delustering agents added (such as titanium dioxide) have very high hardness. While the ...Read more -

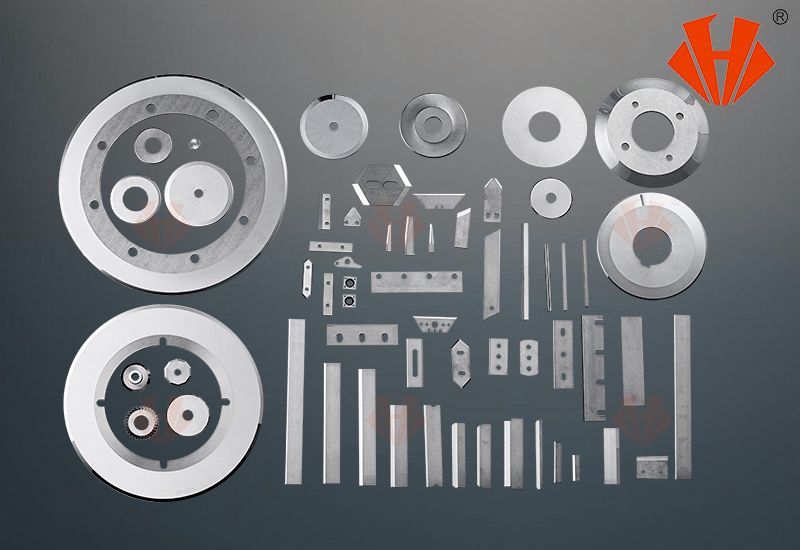

Slitting Knives/Blades in Converting Equipment

The converting industry, we could see the following machines:Film Slitter Rewinders, Paper Slitter Rewinders, Metal Foil Slitter Rewinders...All of them use knives. In converting operations such as roll slitting, rewinding, and sheeting, slitting knives and blades are es...Read more -

Plastic Film Slitter Rewinder Machines & Slitter Blades

Slitter rewinders are essential machines for converting large rolls of plastic films into narrower, usable rolls, primarily through unwinding, slitting, and rewinding processes. They support efficient production in packaging and manufacturing. Common plastic films...Read more -

Challenges in slitting agricultural stretch films & Blade Solutions

While Producing agricultural stretch films presents several specific slitting challenges, and due to film additives and material properties. When using tungsten carbide (WC) blades, the key differences lie in their exceptional hardness, wear resistance, and heat manageme...Read more -

Tungsten Carbide Grades for Chemical Fiber Blades

For different chemical fiber cutting environments, corresponding grades of tungsten carbide materials need to be selected to achieve the best balance between wear resistance and toughness. The following is a performance description of common YG series grades. ...Read more -

The Role of Tungsten Carbide Blades in Film Production

Tungsten carbide blades are essential tools in the film production industry, renowned for their durability and precision. These high-performance blades are commonly used in slitting machines to achieve exact cuts on film rolls, ensuring uniform widths that are crucial fo...Read more -

The challenges met in plastic film slitting and How we tackle them!

Carbide blades are the mainstream choice in the plastic film slitting industry due to their high hardness, wear resistance, and long service life. However, when faced with ever-evolving film materials and increasingly high slitting requirements, they still face a series ...Read more -

Chemical fiber blades in Tungsten Carbide

Tungsten carbide fiber cutting blades are hard alloy (tungsten steel) tools, they are specifically designed for cutting fiber-reinforced composite materials, such as textiles, carbon fiber, glass fiber, and other plastic fiber. Tungsten carbide fiber cutting blades(TC b...Read more