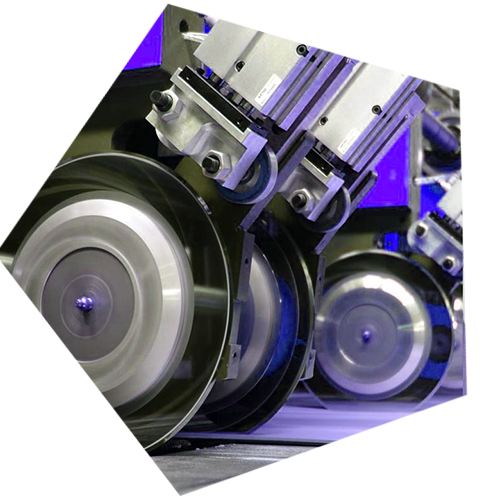

Circular Blades are most applied in industrial Slitting, when come into Corrugated Cardboard Slitting, it requires tungsten carbide blades to address those challenges, such as Rapid Wear, Cutting Quality Issues, Process Compatibility Issues, Mechanical & Installation Issues, Environmental & Cost Challenges...

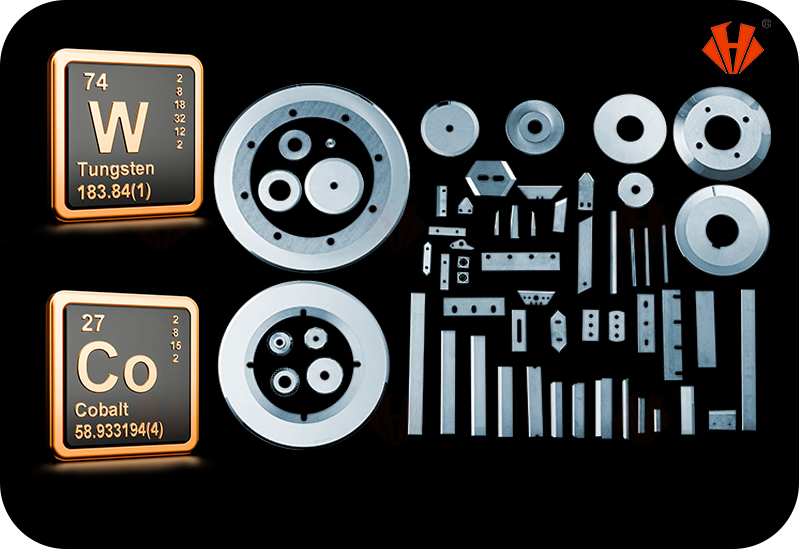

Indusrial Tungsten Carbide Circular Blades

The Circular slitting blades can be devided into groups, according to its application: Corrugated CardBoard Slitting, Tobacco making, metal sheet slitting...Here we line out the most common Circular Knives used in industrial slitting.

1. Tungsten Carbide Circular Blades for Tobacco and Paper Making Industry

These circular blades are engineered for use in cigarette manufacturing machines, specifically designed to slit filter rods into filters. Renowned for their extended service life and clean cutting edges, our knives ensure efficient and precise operations in tobacco processing.

Huaxin's Tungsten Carbide Circular Knives Products

Circular Blades for Tobacco Making

▶ Huaxin Cemented Carbide offers high-quality tungsten carbide blades for tobacco machines, ideal for cutting cigarette filters.

▶ These blades, including carbide circular blades and circular knives, enhance durability and efficiency, reducing downtime.

▶ These blades being compatible with Hauni machines like MK8, MK9, and Protos models...

2. Tungsten Carbide Circular Blades Used In Corrugated Cardboard Slitting

By incorporating various additives into standard tungsten steel grades, these knives achieve enhanced wear resistance, strength, fatigue resistance, and reduced risk of breakage. They are precision-machined to a mirror-like finish, with tight tolerances for the inner hole, parallelism, and end-face runout. Their lifespan ranges from 4 to 8 million meters, far surpassing tool steel knives, offering exceptional cost-effectiveness.

Challenges in slitting?

The circular blades for corrugated cardboard production industry, get the ability to address the challenges in corrugated board slitting, such as:

The precision cutting requires a high quality knife. The slitting speed demands a better cutting blades.

Impurities in corrugated board (e.g., sand particles, cured adhesive lumps) accelerate edge wear, causing rough cuts;

Dull blades increase cutting pressure, leading to edge crushing or face paper separation.

Upper and lower blade rollers may wear at different rates (e.g., anvil blades degrade faster), requiring frequent realignment or replacement and increasing downtime costs.Worn blades generate excessive dust, contaminating equipment and impairing print quality.

Core challenges for carbide tools in corrugated slitting are wear management and cut quality consistency. Manufacturers should address these by:

● Material optimization (e.g., gradient carbide)

● Process parameter adjustment (e.g., reduced feed rate)

● Preventive maintenance (e.g., regular blade alignment checks)

Tailor solutions to production volume, board specifications (e.g., heavier paper wears tools faster), and equipment capabilities.

How to Choose?

Selecting the right slitting thin knife depends on your equipment’s condition:

>Older Equipment: Tool steel thin knives are recommended, as aging machinery may not meet the precision requirements of carbide knives.

>Low-Speed Lines (below 60m/min): High-speed steel knives may not be necessary; chromium steel knives provide good value for money and suit smaller-scale operations.

>Well-Maintained Equipment: Carbide thin knives are the optimal choice, offering an extended lifespan and shorter grinding times. This reduces downtime for knife changes, saving time and lowering production costs.

By evaluating these factors, carton manufacturers can make informed decisions to optimize performance and efficiency in their production processes.

Huaxin's Tungsten Carbide Circular Knives Products

Circular Blades for Corrugated Cardboard Slitting

Huaxin(CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD) provides premium fundamental materials and cutting tools mainly made from tungsten carbide for our customers from different industries across the world, including Corrugated Cardboard cutting, wood furniture making, chemical fiber & packaging, tobacco making...