Hey there, if you're in the textile game, you know cutting short fibers like polyester, nylon, or cotton blends is no joke. It's all about getting clean, precise cuts without fraying or wasting material, especially when you're churning out stuff at high speeds. As a factory specializing in tungsten carbide knives, I've seen firsthand how the right blade can make or break your production line. In this 2026 guide, we'll keep it simple and chatty – no fancy jargon – focusing on how to pick the best tungsten carbide blades for short fiber cutting. These bad boys are tough, last forever, and keep your cuts sharp. Let's dive in.

Why Tungsten Carbide Blades Are Your Best Bet for Short Fibers

In textiles, short fibers can be tricky because they're often synthetic and can wear down regular blades fast. Tungsten carbide shines here: it's 15-20 times more durable than steel, gives you precise cuts, and reduces material waste. Sure, they cost more upfront, but think about the savings in the long run – longer blade life means you're not constantly stopping to swap them out.

Plus, in 2026, with smarter manufacturing tech, these blades integrate well with automated cutters for even better efficiency.

why go for tungsten carbide over cheaper options like stainless steel?

Well, these blades are made from a super-hard mix of tungsten and carbon, often beefed up with cobalt for extra toughness. They're like the superheroes of cutting tools – they handle abrasive fibers without dulling quickly, which means fewer blade changes and less downtime in your factory.

Key Factors to Consider When Choosing Your Blades

Match the Blade to Your Fiber Type

Start with what you're cutting. Short fibers in textiles vary – some are soft and fluffy, others are tough and chemical-based like aramids. For everyday synthetics, go for a standard tungsten carbide grade that's balanced in hardness and flexibility to avoid chipping. If you're dealing with abrasive or recycled fibers, opt for higher cobalt content for more toughness – it prevents the blade from breaking under pressure.

Pro tip: Test a few samples. If your fibers are super fine, a blade with a sharper edge angle (like 30-45 degrees) will slice through without pulling or tearing.

Think About Hardness and Wear Resistance

Tungsten carbide blades are rated by hardness (often around HRC 90+), which is key for longevity. Higher hardness means better wear resistance, perfect for high-volume cutting where blades see thousands of cycles a day. But don't go too hard – super brittle ones might crack on denser fibers.

In 2026, look for virgin tungsten carbide (not recycled) if you want top performance; it's purer and holds an edge longer. Recycled options are cheaper but might dull 10-20% faster. Always check the specs: aim for blades that balance hardness with some elasticity to handle the vibrations in textile machines.

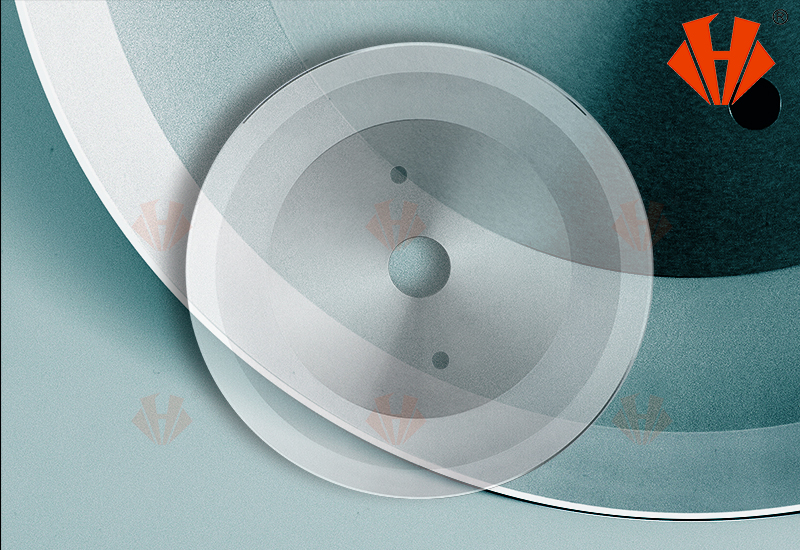

Shape, Size, and Design Matter

Blades come in all shapes – straight, circular, serrated, you name it. For short fiber cutting, circular or rotary blades are popular because they roll through material smoothly in continuous lines. Size-wise, match it to your machine: too big and it won't fit; too small and you'll lose efficiency.

Serrated edges? Great for fibrous stuff that might bunch up, as they grip and cut aggressively. Flat edges work for cleaner, straighter cuts on uniform short fibers. And don't forget coatings – a titanium or ceramic layer can add extra slipperiness, reducing friction and heat buildup, which is huge for preventing fiber melting in synthetics.

Machine Compatibility and Cutting Speed

Your blade has to play nice with your equipment. Check the mounting holes, thickness (usually 0.5-2mm for precision), and RPM ratings. Tungsten carbide can handle high speeds – up to 10,000 RPM in some setups – but if your machine runs hot, pick blades with better heat resistance to avoid warping.

Also, factor in your production speed. For fast-paced textile lines, blades with finer grains in the carbide mix cut smoother and last longer under stress.

Maintenance and Longevity Tips

Even the best blades need love. Sharpen them regularly (tungsten carbide can be resharpened multiple times), store them dry to prevent corrosion, and inspect for chips after heavy use. A good rule: if a blade lasts 5-10 times longer than steel, you're on the right track.

Budget-wise, calculate your total cost – including downtime. A premium tungsten carbide blade might seem pricey, but if it cuts downtime by half, it's a win.

Choosing the right tungsten carbide blade for short fiber cutting boils down to knowing your fibers, prioritizing durability, and matching the design to your setup. Go for quality over cheap knocks-offs, and you'll see smoother operations, less waste, and happier customers in the textile world. If you're running a factory like mine, investing in these blades isn't just smart – it's essential for staying competitive this year. Got questions? Hit me up – let's talk shop!

About Huaxin:Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

custom-engineered blades

Leading manufacturer of industrial blades

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Jan-13-2026