You know what? A bundle of chemical fibers, as thin as a strand of hair, has to withstand thousands of cuts per minute—and the key to cut quality lies in a small blade. In the textile industry, where precision and efficiency are both crucial, tungsten carbide chemical fiber cutter blades are quietly changing the game.

Traditional chemical fiber cutter blades are often made from tool steel or high-speed steel. Over long hours of work, these materials gradually lose their edge, leading to inconsistent cut quality. Workers then have to replace the blades frequently, which hurts productivity and drives up operating costs. The introduction of tungsten carbide has completely changed this. It’s three times harder than regular steel and 5–8 times more wear-resistant.

The core material of these carbide blades is a composite of tungsten carbide and cobalt. This special mix gives the blades outstanding performance: not only is their hardness as high as HV900–1100, but they also stay stable in high-temperature environments. When the blade meets the fiber bundle at speeds of tens of meters per second, the tungsten carbide coating effectively resists heat and wear caused by friction, ensuring every cut is clean and sharp.

The use of laser cladding technology has taken carbide blade performance even further. This process bonds the carbide overlay perfectly with the base material, giving the tool excellent heat resistance, oxidation resistance, and wear resistance all at once. Compared with complicated ultra-hard high-speed steel processing methods, this approach simplifies production and cuts costs, allowing more companies to benefit from technological progress.

It’s also worth highlighting the extremely high cutting precision of carbide blades, which ensures highly consistent fiber lengths. This accuracy is especially important in blending processes, where the even mixing of different fibers directly affects the quality and feel of the final product. When the blade stays sharp, every fiber is cut cleanly and smoothly, with no frayed edges or sticking.

As quality standards in the textile industry keep rising, tungsten carbide chemical fiber cutter blades are becoming the top choice for more and more companies. Their arrival hasn’t just solved practical production pains—it’s also pushing the whole industry toward greater efficiency, energy savings, and precision. In this seemingly small area, progress in materials science is creating enormous value.

From frequent replacements to long-lasting performance, from inconsistent results to precise and repeatable cuts, tungsten carbide chemical fiber cutter blades have proven their worth through solid performance. For modern textile companies focused on both efficiency and quality, choosing the right cutter blade has become a key part of staying competitive. In this specialized field, every technological breakthrough brings new momentum for the industry’s growth.

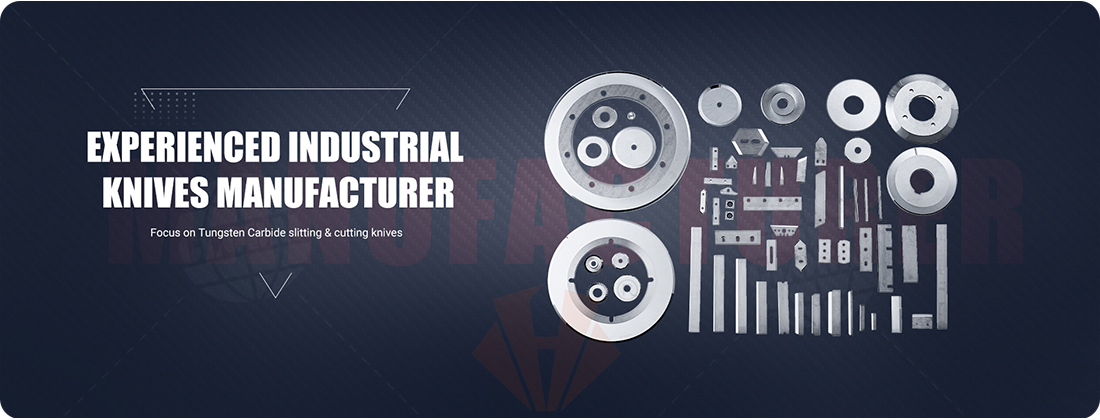

About Huaxin:Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

custom-engineered blades

Leading manufacturer of industrial blades

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Nov-18-2025