Precision and durability are paramount to achieving efficient,In the paper processing industry, high-quality cuts. High-quality industrial tungsten carbide blades are widely used in paper cutting machines due to their superior hardness, longevity, and ability to deliver clean, accurate cuts over long production cycles. These blades, known as tungsten carbide cutter blades, tungsten steel blades, or tungsten razor blades, provide essential benefits that optimize performance in paper cutting applications.

Why Tungsten Carbide Blades Are Essential for Paper Cutting

Paper cutting machines must process large volumes of paper with a high level of precision, often at rapid speeds. To meet these demands, the industry increasingly relies on tungsten carbide blades for their unique properties:

Unmatched Hardness and Durability

Tungsten carbide is one of the hardest materials available, making it exceptionally resistant to wear and abrasion. In paper cutting machines, where blades are constantly exposed to friction and must endure repeated cutting, the high durability of tungsten carbide blades reduces the frequency of replacements. This durability is especially valuable in high-volume paper processing where continuous operation is required to maintain productivity.

Superior Edge Retention and Sharpness

Tungsten steel blades are known for their lasting sharpness, which ensures that each cut is as clean and precise as the last. Unlike conventional steel blades, which can dull quickly, tungsten carbide blades maintain a sharp edge over extended use, leading to higher accuracy in cuts. For paper cutting machines, this reduces wastage caused by uneven or frayed edges, while improving overall product quality.

High Resistance to Corrosion and Impact

In paper cutting environments, blades can be exposed to moisture, ink, and other contaminants. Tungsten carbide's resistance to corrosion helps preserve blade quality, ensuring they stay effective even in harsh conditions. Furthermore, tungsten carbide's high impact resistance allows these blades to handle sudden, high-pressure cuts without chipping or breaking, which is particularly useful in industrial paper processing applications.

Efficiency in High-speed and High-volume Applications

Tungsten carbide's ability to withstand heat and resist deformation makes it an ideal choice for high-speed operations, where friction and heat generation are constant. The thermal conductivity of tungsten carbide helps dissipate heat, preventing the blade from overheating, which is critical in continuous paper cutting machines. This heat resistance also improves blade stability and lifespan, contributing to overall operational efficiency.

Types of Tungsten Carbide Blades for Paper Cutting

In paper cutting applications, various types of tungsten carbide blades are designed to meet different cutting needs:

- Tungsten Carbide Cutter Blades

These versatile blades are commonly used for general-purpose cutting in paper processing. They are suitable for a wide range of paper types, from standard sheets to heavier stock, offering consistent performance across diverse materials. - Tungsten Steel Blades

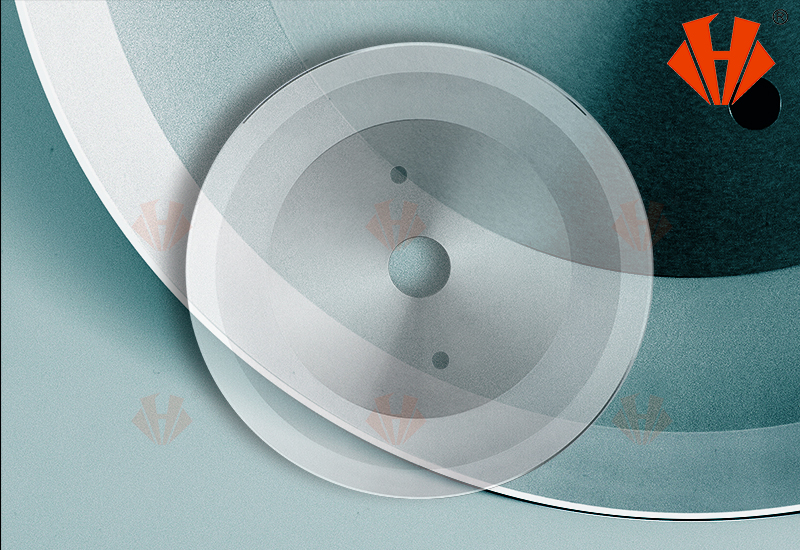

Known for their robustness, tungsten steel blades are used for tasks that demand maximum durability, such as cutting through large volumes of paper or heavier paper types. These blades are highly resistant to deformation and dulling, making them ideal for high-demand applications in commercial printing and paper manufacturing. - Tungsten Razor Blades

With a sharpness akin to a traditional razor, tungsten razor blades are ideal for precision tasks that require ultra-fine cuts. These blades are often used in applications where accuracy and edge quality are essential, such as in cutting specialty papers or in applications that demand high-precision trimming.

Choosing the Right Tungsten Carbide Blade for Paper Cutting Machines

When selecting a tungsten carbide blade for a paper cutting machine, it’s essential to consider factors like paper type, production volume, and the machine's operating speed. High-quality tungsten carbide blades tailored to specific machine models and material requirements are often available from leading manufacturers, who provide customized options to maximize productivity and blade life. The right blade choice can significantly reduce downtime and improve product quality by delivering consistent, smooth cuts.

High-quality tungsten carbide cutter blades, tungsten steel blades, and tungsten razor blades have become essential in paper cutting machines due to their durability, sharpness, and resistance to harsh industrial conditions. These blades help maintain productivity in high-volume, high-speed paper processing environments by delivering precise, reliable cuts over extended periods. For companies in the paper processing industry, investing in tungsten carbide blades is a cost-effective way to achieve better product quality, less downtime, and an overall improvement in cutting efficiency.

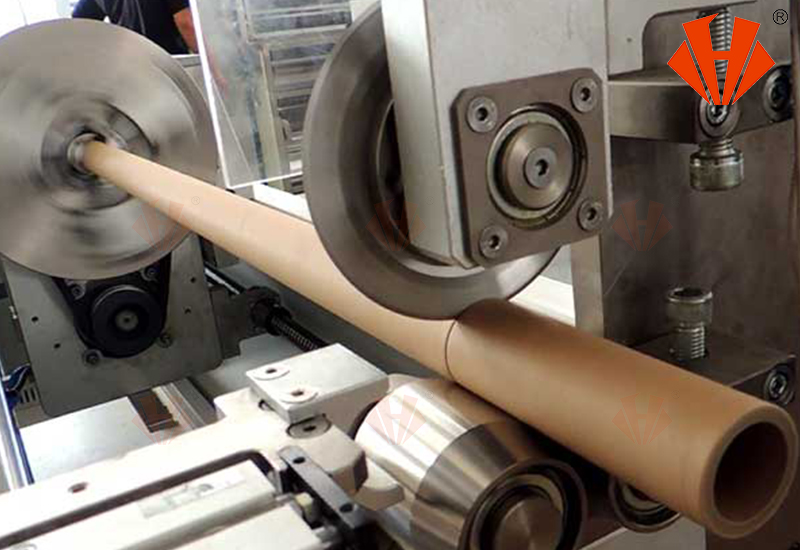

About Huaxin:Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

custom-engineered blades

Leading manufacturer of industrial blades

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Aug-27-2025