Tungsten carbide blades are renowned for their hardness, wear resistance, and cutting performance across various industries. However, to ensure they continue to deliver optimal results, proper maintenance and sharpening are essential. This article offers practical advice on cleaning, sharpening, and storing tungsten carbide blades to maximize their lifespan. We will also provide do’s and don’ts for users in different industries, ensuring that your blades remain in peak condition.

I.The Cleaning of Tungsten Carbide Blades

What should be done?

Regular Cleaning:

Establish a routine for cleaning your tungsten carbide blades after each use. This removes debris, dust, and other contaminants that can dull the blade or cause premature wear.

Use Mild Detergents:

When cleaning, use mild detergents and warm water. Avoid harsh chemicals or abrasives that could damage the blade’s surface.

Dry Thoroughly:

After cleaning, ensure the blade is thoroughly dried to prevent rust and corrosion.

What we should not do?

Avoid Improper Cleaning Tools:

Never use steel wool, brushes with metal bristles, or other abrasive materials to clean tungsten carbide blades. These can scratch the surface and reduce cutting performance.

Neglect Regular Cleaning:

Skipping regular cleaning can lead to a buildup of debris and contaminants, reducing the blade’s lifespan and cutting efficiency.

II. The Sharpening of Tungsten Carbide Blades

1. The things we can do to sharp the tungsten caibide knives

Use Specialized Sharpening Tools:

Invest in specialized sharpening tools designed for tungsten carbide blades. These tools ensure precise and consistent sharpening, maintaining the blade’s edge integrity.

Follow Manufacturer Guidelines:

Always follow the manufacturer’s guidelines for sharpening intervals and techniques. Over-sharpening can weaken the blade’s structure, while under-sharpening can reduce cutting performance.

Regular Inspection:

Regularly inspect the blade for signs of wear or damage. Address any issues promptly to prevent further deterioration.

2. What we should not do

Avoid Improper Sharpening Techniques:

Never attempt to sharpen tungsten carbide blades using improper techniques or tools. This can lead to uneven wear, chipping, or cracking of the blade.

Neglect Sharpening:

Ignoring the need for sharpening can dull the blade, reducing cutting efficiency and increasing the risk of damage during use.

III. Suggestions on Storing Tungsten Carbide Blades

Right:

Store in a Dry Environment:

Keep tungsten carbide blades in a dry, rust-free environment to prevent corrosion.

Use Blade Protectors:

When not in use, store blades in protective sheaths or cases to prevent accidental damage.

Label and Organize:

Label and organize your blades to ensure easy identification and retrieval. This reduces the risk of using the wrong blade for a specific application.

Wrong:

Avoid Exposure to Moisture:

Never store tungsten carbide blades in damp or humid conditions. Moisture can cause rust and corrosion, reducing the blade’s lifespan.

Improper Storage:

Improper storage, such as leaving blades exposed or stacked loosely, can lead to damage or dulling.

More suggestions on maintaining tungsten carbide Industrial knives

Regularly inspect blades for wear and sharpen as needed to maintain cutting precision.

Use specialized sharpening tools designed for tungsten carbide blades to maintain a sharp edge for precise cuts.

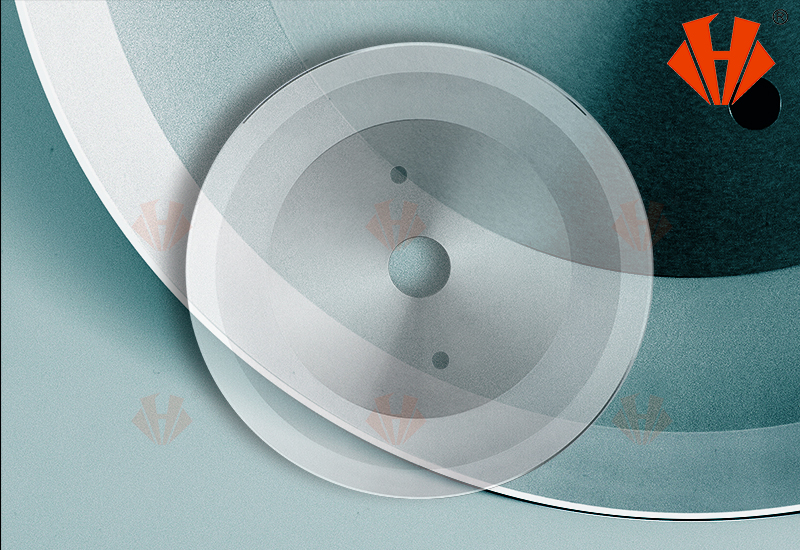

About Huaxin:Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

custom-engineered blades

Leading manufacturer of industrial blades

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Aug-18-2025