Recent trends in China's tungsten market have seen significant price surges, driven by a combination of policy constraints and booming demand. Since mid-2025, tungsten concentrate prices have soared by over 25%, reaching a three-year high of 180,000 CNY/ton. This increase is largely attributed to reduced mining quotas (down 6.45% year-on-year) and stricter environmental policies, which have constrained supply. Meanwhile, demand from sectors like new energy vehicles and photovoltaics has exploded, with tungsten use in EVs tripling and Photovoltaic tungsten filament demand growing by 22%

Tungsten Carbide

For downstream industries like carbide tool manufacturing, this surge has escalated production costs. Hard alloy blades producers face squeezed margins, as tungsten carbide raw material costs rose 30–40% in May–July 2025. Many companies struggle to balance cost pressures while maintaining quality.

However, Chengdu Huaxin (www.huaxincarbide.com) proactively navigated these challenges. By anticipating market shifts, the company secured ample raw material inventories—enough for 3–4 months of production—shielding itself from short-term price volatility. This strategic stockpiling allows Huaxin to continue delivering high-quality, cost-effective carbide blades without compromising on performance.

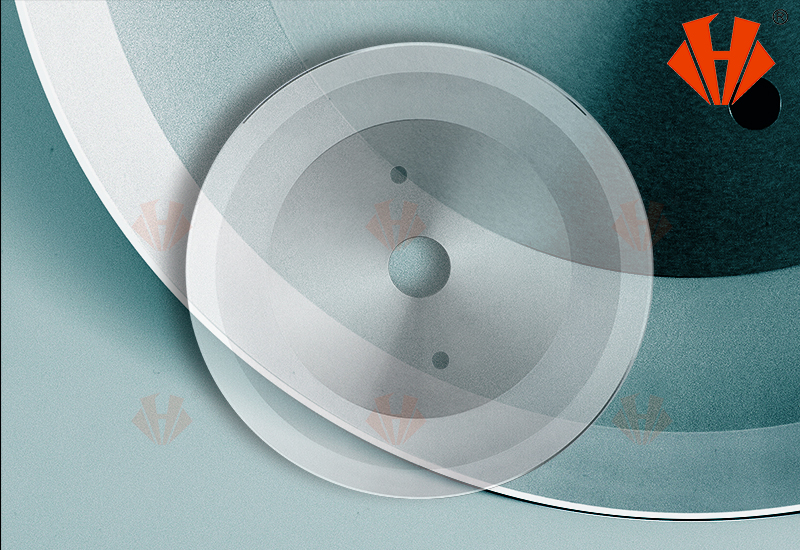

Key products like Tungsten Carbide Thin Blades (used in precision cutting) and Circular Blades for Slitting (ideal for flexible materials) remain consistently available. Similarly, their Carbide Blades for Woodworking (durable for planers and shredders) and Carbide Knives for Tobacco Industry (precision-cut for efficiency) continue to meet client needs reliably.

About Huaxin:Tungsten Carbide Cemented Slitting Knives Manufacturer

Huaxin’s commitment to stability amidst market uncertainty underscores its customer-centric approach. By leveraging inventory management strategies and focusing on value-driven solutions, the company ensures that clients receive superior products without bearing the brunt of raw material inflation. As tungsten prices remain volatile, Huaxin’s foresight and preparation offer a model of resilience in the industrial tools sector.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

custom-engineered blades

Leading manufacturer of industrial blades

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Sep-04-2025