Quality Inspection Items and Equipment for Tungsten Carbide Blades Used in Corrugated Paper Cutting

Quality Inspection Items

1. Dimensional Accuracy Inspection

▶ Items: Length, width, thickness, tolerance, chamfer

Instruments: Vernier caliper, micrometer, profile projector, Coordinate Measuring Machine (CMM)

2. Flatness Inspection

▶ Items: Flatness of both sides of the blade

▶ Instruments: Granite surface plate + dial indicator, optical interferometer

3. Edge Sharpness Test

▶ Items: Cutting edge sharpness

▶ zInstruments: Blade sharpness tester (e.g., cutting force tester, BFT tester)

4. Hardness Test

▶ Items: Blade hardness (usually HRA or HV)

▶ Instruments: Rockwell hardness tester, Vickers hardness tester

Hardness testing is also a very important test. Use a hardness tester to test the hardness of the blades to ensure that the hardness values meet the production requirements. The hardness value of the qualified or not directly related to the wear resistance and life of the blade.

5. Microstructure and Density Check

▶ Items: Cracks, pores, carbide distribution

▶ Instruments: Metallographic microscope, Scanning Electron Microscope (SEM)

6. Coating Thickness & Adhesion Test (if coated)

▶ dInstruments: X-ray coating thickness gauge, scratch tester

7. Dynamic Balancing (for rotating tools)

▶ Instruments: Dynamic balancing machine

Why Choose Chengduhuaxin Carbide?

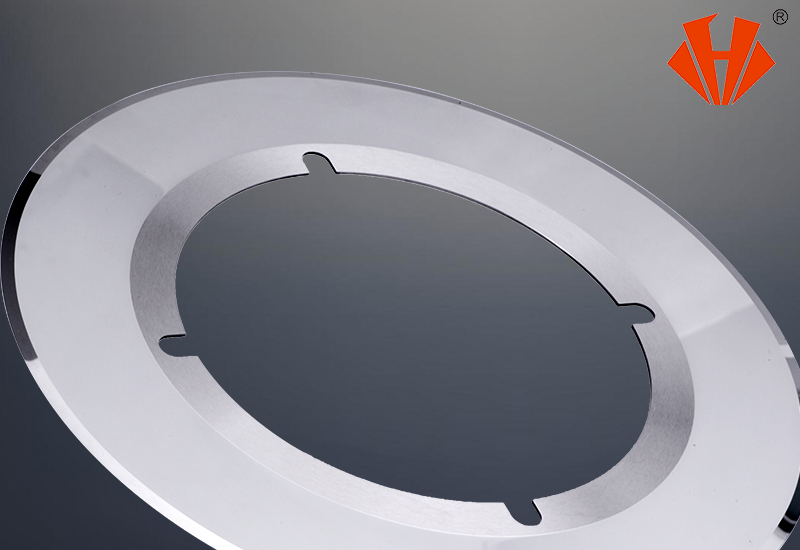

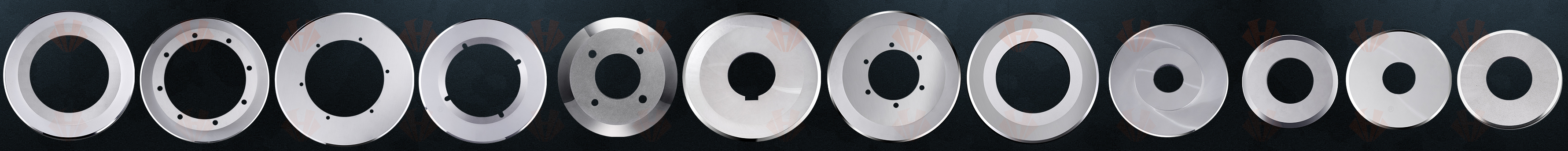

Chengduhuaxin Carbide stands out in the market due to its commitment to quality and innovation. Their tungsten carbide carpet blades and tungsten carbide slotted blades are engineered for superior performance, providing users with tools that deliver clean, precise cuts while withstanding the rigors of heavy industrial use. With a focus on durability and efficiency, Chengduhuaxin Carbide’s slotted blades offer an ideal solution for industries requiring reliable cutting tools.

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Jul-01-2025