The exceptional wear resistance of tungsten carbide blades, while superior to most other cutting tool materials, is nevertheless subject to gradual deterioration through multiple simultaneous mechanisms when operated continuously over extended periods. Understanding these wear processes is essential for developing effective countermeasures and optimizing blade performance in industrial applications.

1. Abrasive Wear

Abrasive wear represents one of the most common and economically significant wear mechanisms affecting tungsten carbide blades in continuous operation. This process occurs when hard inclusions or work-hardened particles in the workpiece material mechanically interact with the blade surface, leading to gradual material removal through micro-cutting and plowing actions. The extreme hardness of the tungsten carbide grains provides considerable resistance to this wear mechanism, but the relatively softer cobalt binder phase is more susceptible to abrasion, potentially leading to protrusion of WC grains and their subsequent fracture or pull-out. Research indicates that abrasive wear is particularly prevalent when machining materials containing abrasive constituents such as silicon-aluminum alloys, composite materials, or workpieces with hardened surface scales.

The rate of abrasive wear is influenced by several factors, including the size and morphology of the abrasive particles, the mechanical properties of both the workpiece and the blade material, and the cutting conditions employed. Industrial observations confirm that abrasive wear typically manifests as a uniform wearing of the tool's flank face or the formation of grooves along the chip-contact surface, with the wear rate generally correlating directly with cutting distance and inversely with cutting hardness

2. Diffusive Wear

Diffusive wear, also known as dissolution-diffusion wear, becomes particularly significant in high-temperature machining applications where cutting temperatures exceed 800°C. At these elevated temperatures, the chemical constituents of both the tungsten carbide blade and the workpiece material become increasingly mobile, leading to mutual diffusion across the tool-workpiece interface. This phenomenon is especially pronounced when machining ferrous materials, where iron from the workpiece can diffuse into the carbide blade while carbon, tungsten, and cobalt from the blade diffuse into the chip material.

The diffusion process fundamentally alters the composition and properties of the blade's surface layers. As carbon atoms migrate from the blade surface, the WC crystals become destabilized, leading to a reduction in overall hardness and mechanical integrity. Simultaneously, the diffusion of cobalt weakens the binding between tungsten carbide grains, further compromising the blade's structural stability. This chemical degradation typically results in the formation of crater wear on the tool's rake face, with the maximum wear depth occurring at the location of highest temperature . Studies have demonstrated that incorporating titanium carbide (TiC) into the tungsten carbide composition can significantly reduce diffusive wear due to TiC's lower diffusion coefficient relative to WC and its ability to form protective titanium oxide layers at elevated temperatures.

3. Adhesive and Chemical Wear

Adhesive wear occurs when microscopic fragments of the workpiece material become welded to the blade surface under the combined influence of high pressure and temperature at the tool-workpiece interface. These adhesive junctions can subsequently fracture during relative motion, leading to the removal of small particles from the blade surface. This mechanism is particularly prevalent when machining ductile materials that have a tendency to adhere to cutting tools, such as aluminum alloys or certain stainless steels.

Simultaneously, chemical wear processes, including oxidation and other thermochemical reactions, can significantly contribute to blade degradation, especially in high-temperature environments. Tungsten carbide can oxidize to form tungsten oxide and carbon dioxide at temperatures exceeding 600°C, while cobalt binder material is similarly susceptible to oxidation, potentially leading to the disintegration of the blade's binder phase and the consequent loss of tungsten carbide grains. The presence of certain chemical elements in workpiece materials, such as chlorine or sulfur in some alloys, can accelerate these chemical wear processes through the formation of volatile or low-strength reaction products.

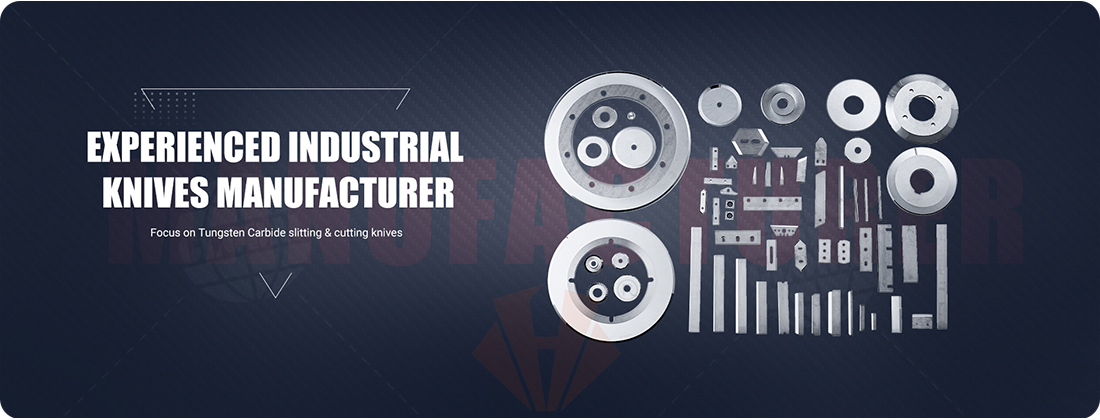

About Huaxin:Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

custom-engineered blades

Leading manufacturer of industrial blades

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Oct-24-2025