I. What are the main factors affecting the quality of carbide tools?

By utilizing the high hardness of tungsten carbide and improving its toughness, a metallic binder is used to bond the tungsten carbide, enabling this material to possess hardness far superior to high-speed steel. Carbide tools offer a series of excellent properties, including high hardness, wear resistance, good strength and toughness, heat resistance, and corrosion resistance. In particular, their high hardness and wear resistance remain largely unchanged even at 500°C and remain high at 1000°C.Factors influencing the characteristics and applications of carbide tools include:

1.Challenging workpiece materials,

such as alternative metals and difficult-to-machine alloys. Some of these materials have machinability less than 1/4 that of steel, and some can cost hundreds of dollars per pound.

2. Increasingly complex workpiece geometries

such as thin-walled workpieces and intricately shaped aerospace components.

3. Large-sized workpieces

particularly the growing demand for turbine and heavy machinery parts. The high per-unit cost of these workpieces places significant demands on carbide tool machining.

4. Increasingly specific quality and performance requirements,

such as demands for improved fatigue strength on the surface of machined parts.

Analysis of factors determining the quality of carbide tools:

(I) Hardness and Toughness

Carbide tools possess a unique advantage in balancing hardness and toughness. Tungsten carbide (WC) itself has very high hardness (exceeding that of corundum or aluminum oxide) and maintains this hardness even at elevated temperatures. However, it lacks sufficient toughness, which is essential for cutting tools. To leverage the high hardness of tungsten carbide while improving its toughness, a metallic binder is used to bond the tungsten carbide. This results in a material that not only far exceeds the hardness of high-speed steel but also withstands the cutting forces in most machining applications. Additionally, it can endure the high temperatures generated during high-speed machining. Therefore, the suitability of carbide tool performance for specific machining tasks largely depends on the initial powder manufacturing process.

(II) Powder Manufacturing Process for Carbide Tools

Tungsten carbide powder is produced by carburizing tungsten (W) powder. The characteristics of the tungsten carbide powder (especially its particle size) are primarily determined by the particle size of the raw tungsten powder and the temperature and duration of the carburization process. Chemical control is also critical, as the carbon content must remain constant (close to the theoretical stoichiometric ratio of 6.13% by weight). To control the powder particle size in subsequent processes, small amounts of vanadium and/or chromium may be added before carburization. Different process conditions and machining applications require specific combinations of tungsten carbide particle size, carbon content, vanadium content, and chromium content. Variations in these combinations can produce a wide range of tungsten carbide powders.

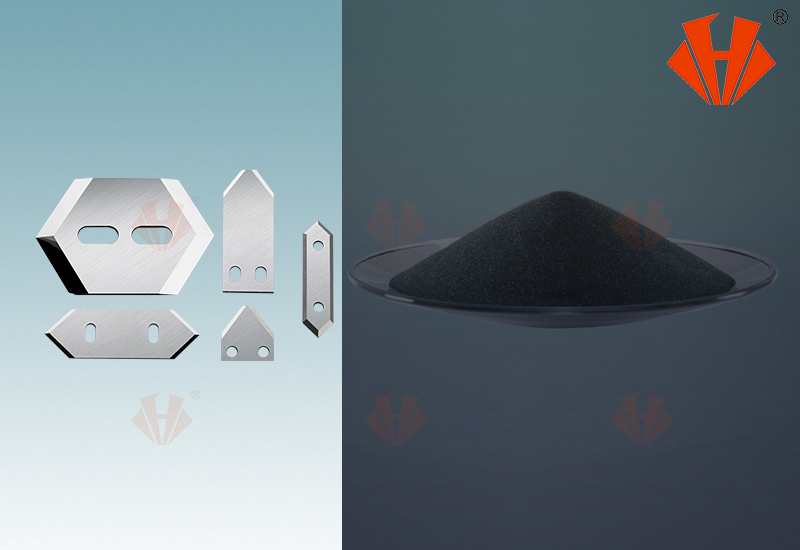

About Huaxin:Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

custom-engineered blades

Leading manufacturer of industrial blades

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Sep-14-2025