First Off: What Are These Materials Anyway?

Let's start with the basics. HSS is a type of steel that's been jazzed up with elements like tungsten, molybdenum, and chromium to make it tougher and able to handle heat without losing its edge. It's been around forever and is super common in tools because it's affordable and easy to work with.

On the flip side, tungsten carbide is a beast – it's not pure metal but a composite of tungsten and carbon, often mixed with cobalt to bind it. Think of it as super-hard ceramic-like stuff that's way denser and more resistant to wear than regular steel. TC knives are the go-to for heavy-duty jobs where blades get beat up a lot.

In corrugated paper slitting, your knives are spinning or slicing through layers of paperboard at high speeds. The material isn't super hard like metal, but it's abrasive – those fibers can grind down a blade over time, leading to dull edges and messy cuts.

Head-to-Head Comparison: TC vs. HSS

Hardness and Wear Resistance

This is where TC crushes it. Tungsten carbide is insanely hard – we're talking up to 3-4 times harder than HSS. That means it stays sharp way longer when dealing with the gritty texture of corrugated board. HSS is tough, but it wears out faster because those paper fibers act like sandpaper on the edge.

In practice? If you're running a high-volume line, TC knives might last 5-10 times longer before needing a sharpen or replacement. That translates to less downtime and fewer headaches. HSS? It's fine for lighter jobs, but expect to swap or sharpen them more often.

Cutting Quality and Precision

Clean cuts are everything in corrugated slitting – you don't want frayed edges or dust buildup that clogs your machine. TC blades, with their finer grain and sharper edges, deliver smoother, burr-free slices. They handle the varying densities in corrugated paper (flutes and liners) without skipping a beat.

HSS blades can get the job done, but they dull quicker, leading to rougher cuts over time. Plus, they're not as precise for super-thin or high-speed slitting. If your operation demands top-notch finish quality, TC is your buddy.

Toughness and Durability

HSS wins a point here for being more flexible and less brittle. It can take a bit of impact or vibration without chipping, which is handy if your machine setup isn't perfect or if there's occasional debris.

TC is harder, but that makes it a tad more prone to chipping if hit wrong – though modern grades with added cobalt make it tougher. For corrugated paper, which isn't as punishing as metal cutting, TC's durability shines through without much risk of breakage.

Cost and Value

Upfront, HSS is the budget king – knives made from it are cheaper to buy and easier to sharpen in-house. If you're a small shop with low production, this could save you bucks.

But TC? Yeah, it's pricier at first (maybe 2-3 times more), but the long-term savings are huge. Longer life means fewer purchases, less labor for changes, and better efficiency. In the paper industry, where downtime costs money, TC often pays for itself quick.

Maintenance and Sharpening

HSS is forgiving – you can sharpen it multiple times with basic tools, and it holds up okay. But you'll be doing it more often.

TC needs specialized equipment to sharpen (like diamond wheels), but since it dulls slower, you sharpen less. Plus, many TC knives can be resharpened several times before they're done. Pro tip: Keep 'em clean and cool during use to max out lifespan.

So, Which One Wins for Corrugated Slitter Knives?

Tungsten carbide is the clear winner for most corrugated paper slitting ops. Its superior wear resistance, longer life, and cleaner cuts make it ideal for handling the abrasive nature of cardboard without constant interruptions. Sure, HSS is cheaper and tougher in some ways, but if you're aiming for efficiency, quality, and cost savings over time, go TC.

That said, if your setup is low-volume or budget-tight, HSS could still be a solid pick. Test both in your machine if you can – every line is different. In the end, the right choice keeps your boxes shipping smooth and your profits up. Got more questions on blades? Let's chat!

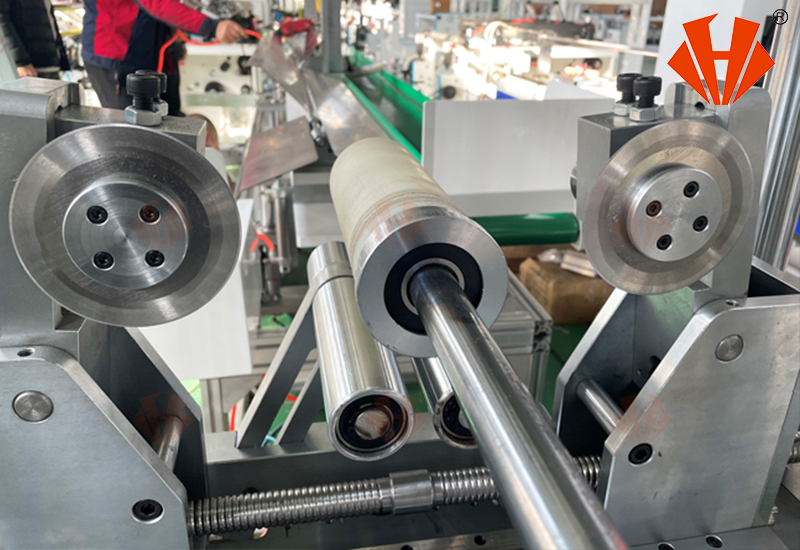

About Huaxin:Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

custom-engineered blades

Leading manufacturer of industrial blades

Customer common questions and Huaxin answers

That depends on the quantity, generally 5-14days. As an industrial blades manufacturer, Huaxin Cement Carbide plans the production by orders and customers' requests.

Usually 3-6 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

Usually T/T, Western Union...deposits firstm, All first orders from new customers are prepaid. Further orders can be paid by invoice...contact us to know more

Yes, contact us, Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

To help you get the best blade, Huaxin Cement Carbide may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

There are many ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. contact us to know about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance.

Post time: Jan-15-2026