Fiber Precision Slitter Spare Parts Cutting Blades

Textile/Yarn/Chemical fiber Slitter/Cutting Blades

Fiber Precision Slitter Spare Parts Cutting Blades

Chemical fiber cutting

Fiber Precision Slitter Spare Parts Cutting Blade is a specialized blade designed to cut synthetic fibers. such as polyester, nylon, and other man-made fibers.

These fibers are stronger and more harder than natural fibers which requires specialized blades to ensure a clean and Precision Slitting.

The right blade can enhance the efficiency,reduce waste and minimize the risk of damage to the fibers.

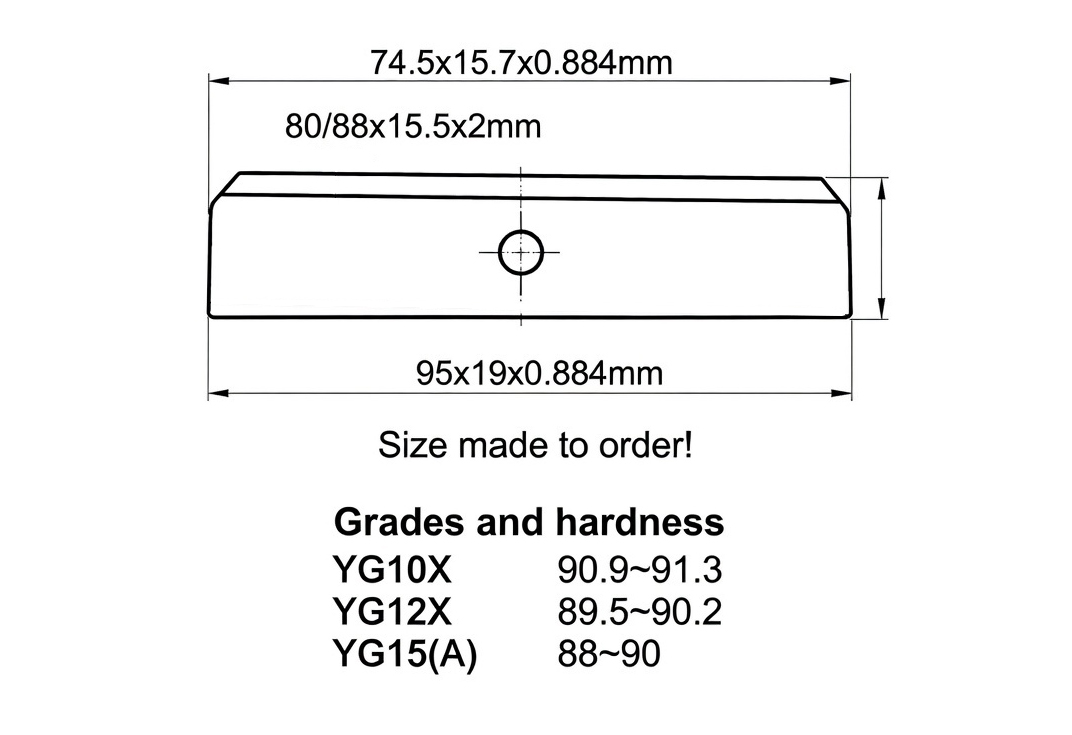

Size

Size of theses Industrial Thin Knives:

Customization is surpported

How to choose the Chemical fiber cutting blades?

To select a fiber Precision Slitter blades,the following factors shoud be taken into consideration.

1. Material.

The blade should be made from a strong and durable material (such as tungsten carbide), which will resist wear and extend the life of the blade.

2.The geometry.

A sharp, straight edge that will allow for a clean and precise cut. The edge should also be able to withstand the pressure and stress of cutting through tough fibers.

3. surface finishment.

To enhance the efficiency,A smooth and polished surface will reduce friction and increase the life of the blade.

A dull blade will generate more heat during the cutting process, which can cause the fibers to melt and become damaged.

Applicatiton

The production process of chemical fiber products.

It's important to cut continuous yarns, chemical fiber filaments, fiber bundles or chemical fiber fabrics according to a certain length or shape.

For example, in the front process of chemical fiber textile, the rolled chemical fiber raw material yarn is cut into fiber segments of a specific length according to production requirements for subsequent processing, such as spinning, weaving, etc.

Since chemical fiber materials usually have a certain toughness and strength, the knife needs to be able to cut quickly and cleanly, so the blade of the chemical fiber knife is specially ground and processed to ensure that it has excellent cutting performance.

Advantages

Inhouse quality inspection procedures ensure strict tolerance requirements;

Outstanding adaptability in various cutting environments,

Extremely precise cuts without unraveling;

Micro-grain carbide guarantees durability and excellent wear resistance;

Fewer blade changes improve productivity;

NO rust and contamination of chemical fibers;

Low levels of material waste/scrap.

The Manufacturer

Huaxin Cemented Carbide focuses on the manufacture of custom-engineered tungsten carbide blades, including standard designs, modified standard knives, and fully customized solutions. From raw powder preparation to sintering and precision grinding, our integrated manufacturing process enables us to deliver near-net shaped carbide tools tailored to specific machines, materials, and cutting conditions across diverse industries.